Showroom

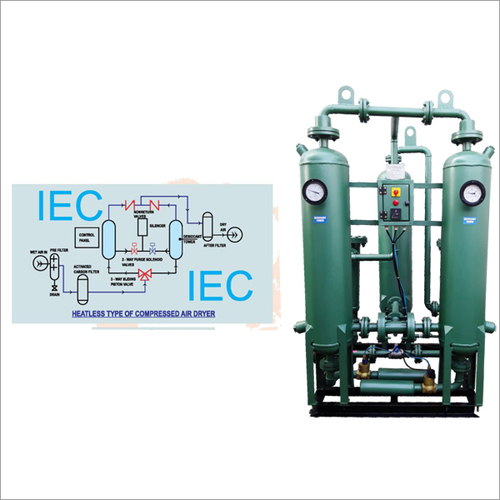

Compressed Air Dryers are used as moisture removing solution for high pressure based air. Available with 1 year of warranty period, these equipments can be operated under 220v to 240v voltage range.

Air/Gas Receiver/Pressure Vessels are reckoned for their adequate storage space, 10.0 C working pressure and long lasting quality. These ergonomically designed products have compact shape and these can endure corrosion.

Auto Drain Valves have been designed as per international norms. Offered with 1 year of warranty period, these are equipped with O ring seal, viton seal, manual test switch and timer etc.

Compressed Air Filters are acknowledged for their long lasting quality, excellent filtration performance and wide working temperature. Simple to install, these air filtering solutions have user friendly design and stable operation.

Provided Pneumatic Components / Accessories are acknowledged for their international standard. Accessible in different specifications, these are appreciated for their long lasting quality, high performance, reasonable price and simple installation method.

Reciprocating Air Compressors are AC powered systems that are reckoned for their lubrication free mechanism, These are considered as Eco-friendly equipments for their noise free operation. These require 220v to 240v voltage range to operate.

Compressed Air Piping Systems are known for their modular structure, availability with standard parts and uninterrupted operation. Low maintenance design, low operating cost, precise diameter and competitive price are their key features.

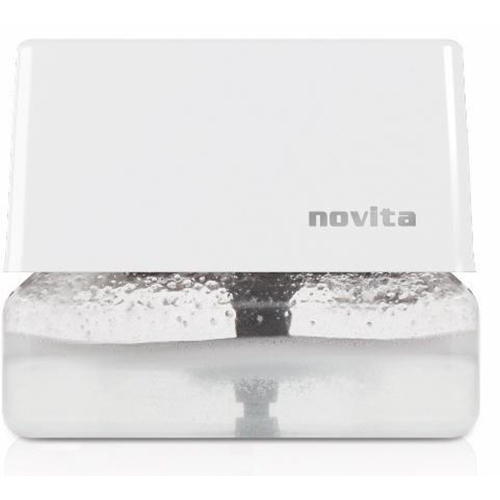

Dehumidifiers are acknowledged for their microcomputer based operation and wide operating temperature range. R-134a refrigerant used by these systems ensures about their environment friendly mechanism. Prolonged working life is one of their key features.

Plate Heat Exchangers are known for their uninterrupted functioning. These can be operated under maximum 200 degree C temperature and 40 bar of operating pressure. Good thermal performance and user friendly mechanism are their key features.

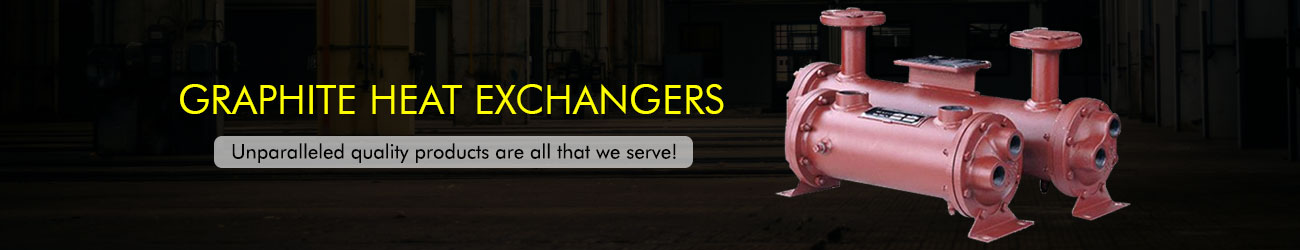

Heat Exchangers are used for transferring of heat from one fluid to other without mixing these two types of fluids. These systems are offered with powder coated or sand blasting treated or polished surface finish based option.

Industrial Chilling Plant are acknowledged for their long service life and application of latest digital control technology. These use R22 refrigerant that promotes emission free operation of these systems.

Provided Air Purifiers are acknowledged for their semi automatic operation. These consist of standard components like a number of sensors and built in ionizer. Quality of these equipments has been verified on the basis of their working life.